Rice University Students Develop Low-Cost Cold Spray Metal 3D Printer

April 26, 2024

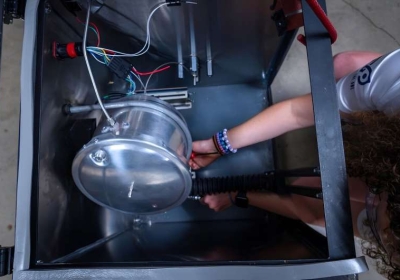

A team of Rice University students has developed a cold spray metal 3D printing system, presenting a compelling alternative to conventional methods. Their printer leverages pressure and velocity instead of temperature to fabricate intricate metal components. The device’s affordability and potential to lower the cost of metal additive manufacturing could significantly impact industries reliant on metal components.

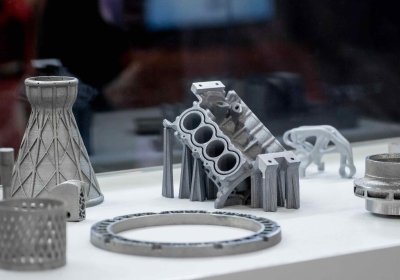

The system’s capacity to manufacture and repair complex metal parts without compromising their structural integrity makes it exceptionally appealing for diverse applications, including automotive, oil and gas, and defense sectors. Unlike traditional metal 3D printers that utilize heat, this device employs cold spray technology, ensuring the preservation of the metal’s properties while achieving precise deposition.

The team’s relentless pursuit of cost reduction culminated in the creation of a device built for less than $5,000, representing a monumental cost saving compared to traditional metal printers that often exceeds $1 million. Rigorous safety measures, including the implementation of complex monitoring systems and adherence to strict operational protocols, guarantee the device’s safe utilization.

This student-led initiative highlights the potential for affordable, high-quality metal 3D printing solutions, offering industries a practical and economically viable alternative for their manufacturing and repair needs. The project also demonstrates the significance of interdisciplinary collaboration and effective project management, highlighting the tangible application of classroom knowledge in real-world scenarios.

Source: news.rice.edu